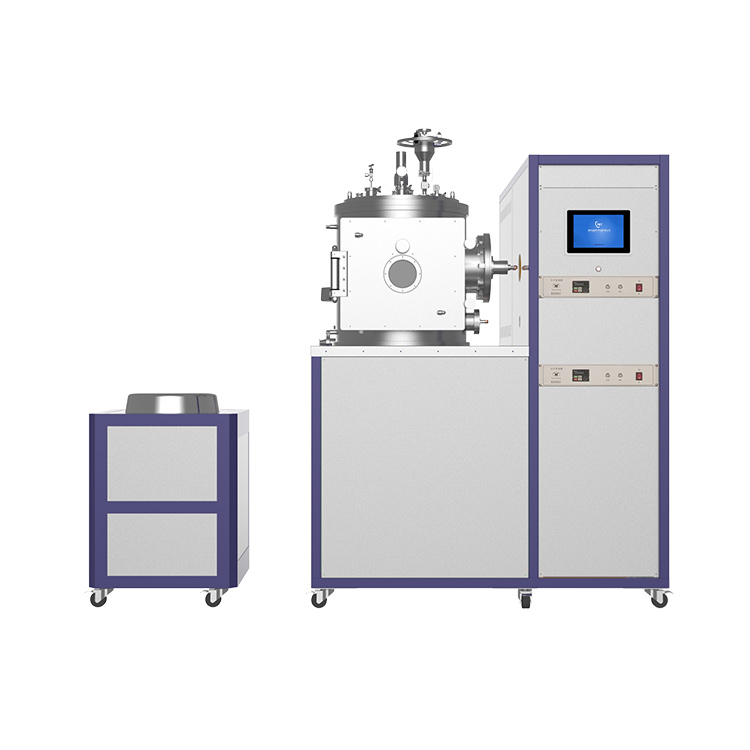

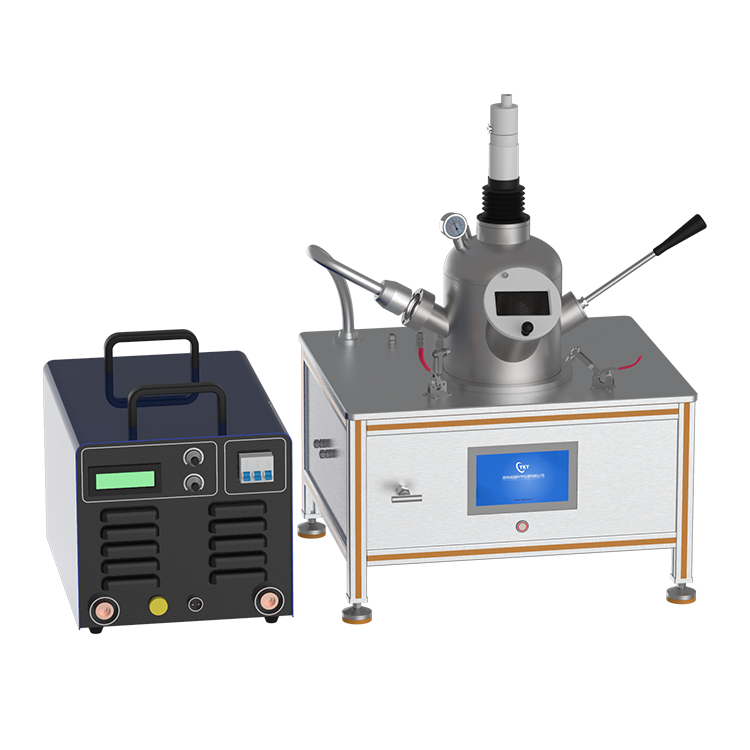

The ultra-high temperature and large-capacity non-consumable high-vacuum arc furnace is a product meticulously developed and designed by our company based on the experimental requirements of scientific research institutions. It is mainly used for melting refractory metals and alloys, as well as for smelting, purification, deoxidization, impurity removal, and other processes. It is particularly suitable for vacuum smelting or small-batch preparation of new materials in universities and scientific research institutions.

II. Equipment Composition:

It mainly consists of an arc melting vacuum chamber, arc gun, arc melting power supply, five-station water-cooled copper crucible, flipping manipulator, working gas circuit, system pumping, vacuum measurement and electrical control system, installation machine base, and other components.

III. Main Structure Description:

This product mainly consists of an arc melting vacuum chamber, upper electrode, lower electrode, furnace door opening mechanism, upper electrode electric lifting mechanism, vacuum system, and arc power supply system.

4.1 Arc Melting Vacuum Chamber: It adopts a double-layer water-cooled structure, with the inner and outer layers welded from stainless steel and treated with a matte surface finish. The inner wall is precisely polished. The furnace body is equipped with a flipping manipulator for melting and flipping samples. It is also equipped with observation windows, vacuum interfaces, filling and venting valves, etc. The furnace cover is equipped with an upper electrode interface, featuring a novel structure and an elegant appearance.

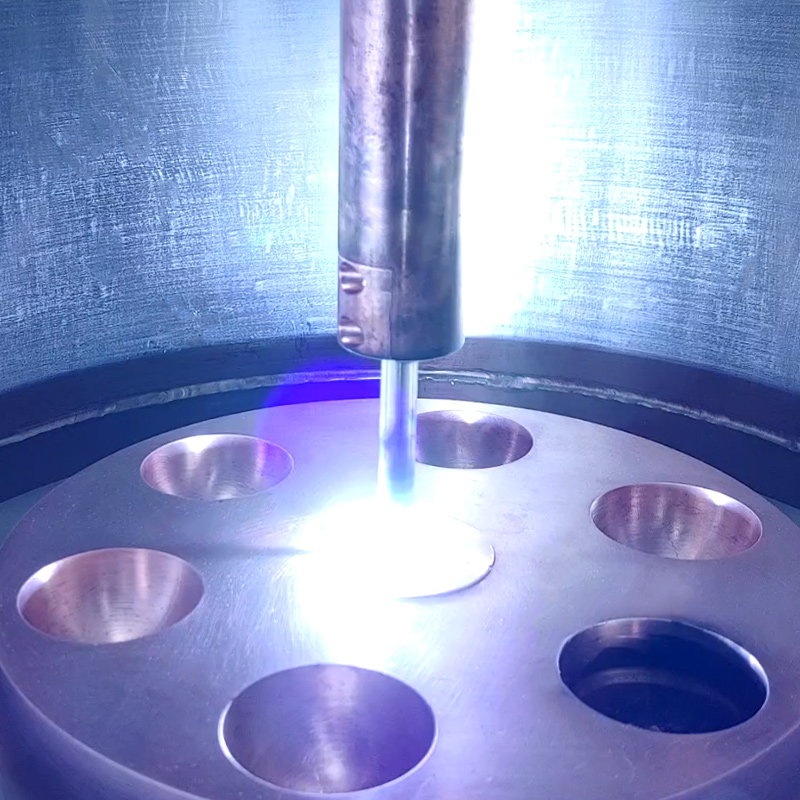

4.2 Upper Electrode and Upper Electrode Lifting Device: The upper electrode and lifting device adopt a Socket type universal design (Note: The term " Socket type universal " is not standard English terminology; it could be interpreted as a universal or omnidirectional design for simplicity), allowing 360-degree free rotation. The electrode lifting adopts screw lifting and electric adjustment, providing convenient and flexible adjustment. The interface adopts welded bellows connections to ensure reliable vacuum sealing.

4.3 Furnace Door Opening: The furnace door is manually opened, making it easy to operate and simple to load and unload materials.

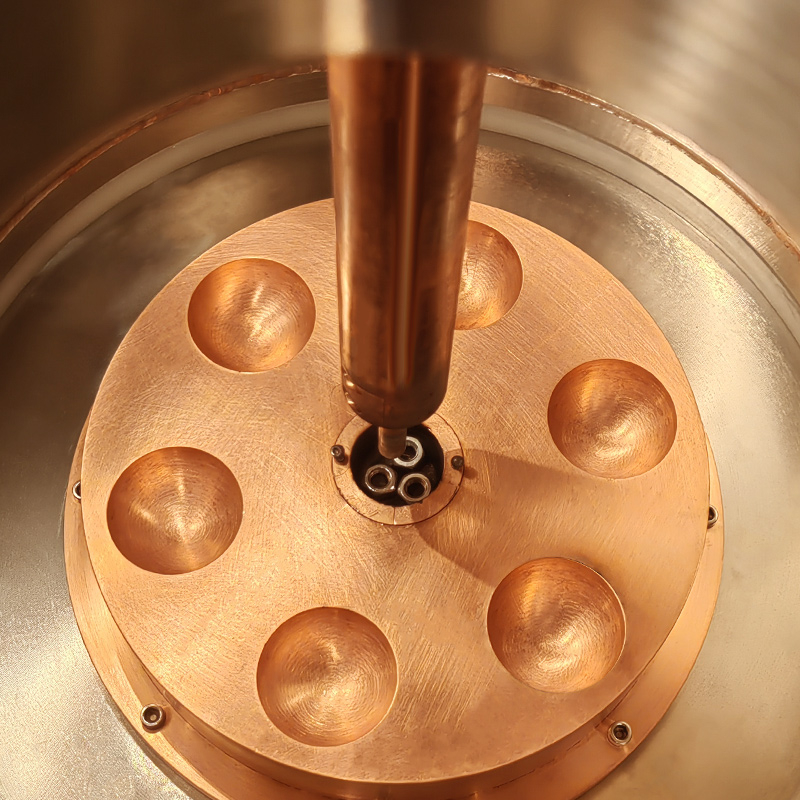

4.4 Water-Cooled Copper Crucible: The water-cooled copper crucible is made of copper and comes in different volumes, allowing selection based on the amount of material to be melted.

4.5 Vacuum System: The vacuum system consists of a Japanese imported magnetic levitation molecular pump, an oil-free fore pump, an INFICON BPG400 composite vacuum gauge, three pneumatic vacuum valves, and various piping, ensuring a vacuum level better than 8x10-4Pa.

4.6 Power Control System: The control system and furnace body adopt an integrated design, and an analog screen is installed. The operation buttons are modularly arranged according to their functional purposes, with analog graphics for high recognition and easy operation. The arc power supply adopts a dedicated power supply for arc melting, featuring high safety and stability. The circuit is equipped with water cut-off alarm and protection functions.

IV. Equipment Features:

1. The furnace body is designed with 304 stainless steel, featuring an elegant appearance and rust resistance.

2. The vacuum chamber adopts a vertical double-cylinder water-cooled structure, allowing for long-term vacuum smelting.

3. It is equipped with a large-diameter observation window for real-time observation of the smelting situation inside the furnace, and comes with an anti-glare filter.

4. High smelting temperature, reaching above 3500 degrees Celsius.

5. It adopts a dedicated pulse power supply for arc melting, featuring high efficiency and long lifespan.

6. Equipped with an operating console and manipulator for more convenient operation.

7. Equipped with a touchscreen display control system for intuitive display of control data, making equipment operation simple and easy without professional training. It records vacuum level, pressure, smelting current, and smelting voltage data.

8. Equipped with imported vacuum units, with gate valves, shut-off valves, and bypass valves for programmed automatic vacuuming with safety protection, effectively preventing manual damage to the molecular pump caused by misoperations.

9. It comes with a water-cooled unit, eliminating the need for additional cooling water circuits.

10. Equipped with a professional imported infrared temperature measurement probe for monitoring the smelting temperature and providing over-temperature protection.

11. The water-cooled copper-tungsten electrode can move 360 degrees, providing flexible operation. It also comes with multiple sets of water-cooled crucibles, which can be installed based on the amount of material to be melted.

12. Equipped with a manipulator for flipping materials, allowing the materials to be flipped during the smelting process for more uniform smelting.

13. The samples can be in powder, wire, chip, drilling swarf, granular, strip, ring, sandy, and other forms.

14. Equipped with a professional camera for monitoring the smelting process, with color reminders on the display screen and software for recording the process to achieve visualization of smelting.

Equipment Parameters of High-Vacuum Arc Furnace:

Product name | Ultra-high temperature, large capacity, non-consumable high vacuum electric arc furnace |

Product model | CY-DHLΦ400-SS-Φ4-F |

Cavity material | 304 stainless steel |

Cavity structure | Double-layer water-cooled |

Cavity size | Diameter about 400mm, height about 350mm |

Smelting electrode | Water-cooled copper-tungsten composite structure |

Arc striking method | High-frequency arc initiation; |

Smelting current | ≦2000A |

Protective gas | Argon |

Molecular pump | Hengyue molecular pump |

Pre-stage pump | Feiyue vacuum pump |

Vacuum gauge | Yinfukang BPG400 composite vacuum gauge |

Equipment limit vacuum | 8×10-4Pa |

Equipment power | <105kW |

System pumping speed | Pumped from atmosphere to 7×10-3Pa≤45min |

Smelting crucible | ≦200g |

Safety protection | To ensure the safe use of the equipment, system detection and protection functions are configured, such as: water shortage and undervoltage detection and protection, strong power phase sequence detection and protection, temperature detection and protection, vacuum system detection and protection, etc. |